Your trusted tarp supplier for all your tarp needs

Reevoo is your first choice for all your tarp needs. Whether you are a homeowner looking to protect outdoor furniture from the elements, a construction professional in need of heavy-duty construction tarps, or an explorer seeking reliable camping gear, we have what you need. With years of industry experience, we have earned a reputation as a trusted tarp supplier, consistently delivering quality products and exceptional service.

We are committed to customer satisfaction, so we offer a wide range of tarp options, including PVC tarps

PVC covers, PE tarps, PE covers, PVC finished products, tarp accessories, PVC light box cloth, PVC transparent film, high-frequency welding machine, PET film for optical glass protection, PVC / PE truck cover, all designed to meet a variety of needs and budgets. We understand that every tarp has a unique purpose, and our team of experts is here to help you find the perfect solution. When you choose Reevoo, you can be confident that you are not only investing in a top-notch tarp, but also investing in a trusted partner who values your satisfaction above all else. For all your tarp needs, we have it covered.

What is PVC Tarpaulin

PVC tarpaulins are customizable and come in a variety of sizes, colors, and thicknesses. When buying a PVC tarpaulin, it's important to consider the manufacturing process, including the fabric weight, coating thickness, and UV inhibitors. You should also ensure that the tarps are well reinforced during manufacture.

-

PVC coated canvas tarpaulin material for truck cover

Add to Inquiry -

Add to Inquiry

-

Grade A Coated PVC Fabric Stocklots

Add to Inquiry -

Grade A Coated PVC Fabric in Stock

Add to Inquiry -

Add to Inquiry

-

Grade A Coated Tarpaulin PVC in Stock

Add to Inquiry -

Grade A Coated Tarpaulin Stocklots

Add to Inquiry -

Add to Inquiry

-

Grade A PVC Coated Tarpaulin Fabric Stock

Add to Inquiry

1.Regular PVC Tarpaulin

2.Heavy Duty PVC Tarpauli

3.Fire-Retardant PVC Tarpaulin

4.Translucent PVC Tarpaulin

5.Clear PVC Tarpaulin

6.Flex Banner PVC Tarpaulin

7.Mesh PVC Tarpaulin

8.Reinforced PVC Tarpaulin

9.Printable PVC Tarpaulin

10.Insulated PVC Tarpaulin

11.Anti-Static PVC Tarpaulin

12.Vinyl-Coated Polyester (VCP) Tarpaulin

Material of PVC Tarpaulin

PVC tarpaulin is typically made from a combination of materials, with the primary components being a fabric base and a polyvinyl chloride (PVC) coating. Here’s a breakdown of the materials used in PVC tarpaulin:

1.Fabric Base:

The base fabric of PVC tarpaulin can be made from various materials, with the most common being:

*Polyester: Polyester fabric is known for its strength, durability, and resistance to stretching and shrinking. It is a popular choice for tarpaulins that require high tensile strength and tear resistance.

*Cotton: Cotton fabric is less common for heavy-duty PVC tarpaulins but may be used for lighter-weight versions due to its breathability and lower cost.

*Polyethylene (PE): In some cases, a polyethylene fabric may be used as the base, especially for tarpaulins that need additional flexibility and resistance to chemicals.

*Vinyl-Coated Polyester (VCP): This is a fabric where the polyester threads are coated with vinyl before being woven into a fabric. It offers excellent strength and resistance to abrasion and is often used in industrial applications.

2.PVC Coating:

The fabric base is then coated with a layer of polyvinyl chloride, which is a type of plastic known for its durability, flexibility, and resistance to water and chemicals. The PVC coating can vary in thickness, with thicker coatings providing enhanced protection and durability.

3.Additives:

Depending on the intended use of the tarpaulin, various additives may be included in the PVC coating to enhance its properties. These can include:

*UV Stabilizers: To protect the tarpaulin from degradation caused by sunlight.

*Fire Retardants: To reduce the flammability of the material.

*Anti-Static Agents: To prevent the build-up of static electricity, which can be hazardous in certain environments.

*Biocides: To inhibit the growth of mold and mildew.

*Colorants and Pigments: To provide the tarpaulin with different colors and patterns.

4.Reinforcements:

For added strength and durability, PVC tarpaulins may also include reinforcements such as:

*Rods or Ribs: For structural support and to prevent sagging.

*Eyelets: For easy installation and securing with ropes or bungee cords.

*Webbing: Strips

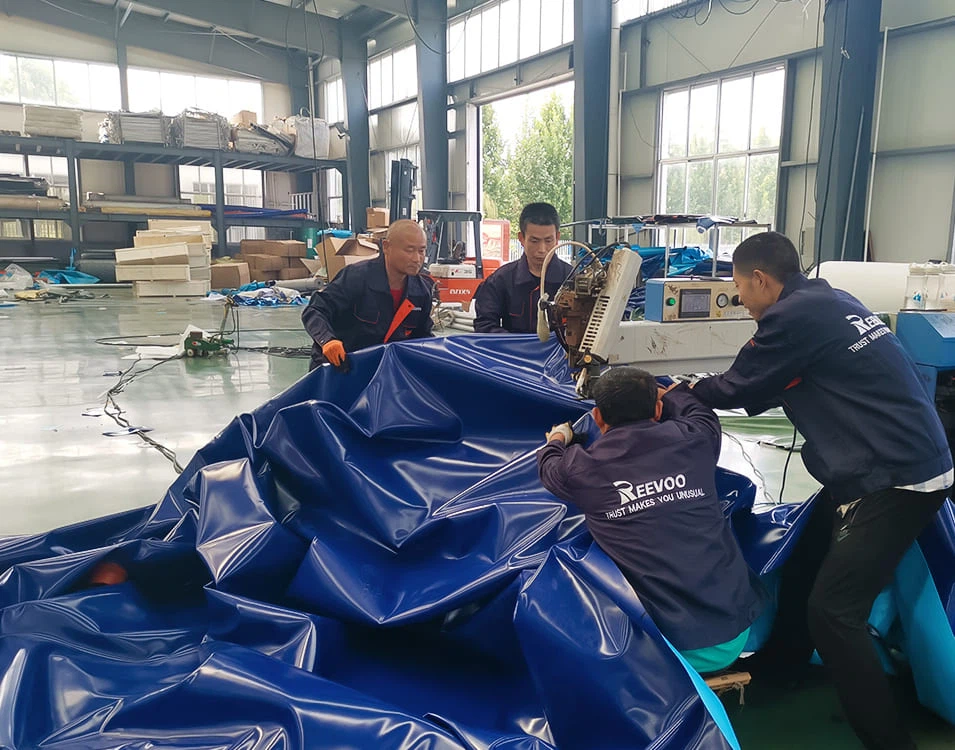

Process of PVC Tarpaulin

Mixing

1

>>

Melting

2

>>

Extrusion

3

>>

Coating

4

Advantages of PVC Tarpaulin

PVC tarpaulins, or polyvinyl chloride tarpaulins, have many advantages that make them ideal for a variety of uses:

Durability

PVC tarpaulins are strong and can withstand harsh weather conditions, heavy use, and tearing, punctures, and abrasions. They are preferred over polyethylene (PE) tarps for more demanding applications because of their superior strength and durability.

Weather protection

PVC tarpaulins are resistant to water, mildew, cold, aging, and static electricity, and can provide a high level of weather protection from rain, snow, and sunlight.

Flexibility

PVC tarpaulins are flexible and come in different thicknesses for different duty levels, such as medium duty (550g), heavy duty (700g), and extra heavy duty (800g).

Versatility

PVC tarpaulins have many applications across industries such as construction, agriculture, transportation, camping, manufacturing, mining, and sports. They can be coated with substances like nylon and cotton, and can be used as temporary roof coverings.

Application of PVC Tarpaulin

PVC tarpaulins are flexible, durable, and versatile sheets made from synthetic plastic materials that can be used in many industries and applications:

-

Construction

Protect tools, materials, and partially built or damaged structures from rain, dirt, dust, and sunlight

-

Agriculture

Cover crops, hay stacks, and grain storage to protect from the elements and reduce water evaporation

-

Transportation

Cover trucks, trailers, and other vehicles to protect cargo and from the weather

-

Camping

Create temporary shelters and tents for outdoor events, disaster relief, and camping

-

Other

Use as curtains, barriers, or shelters, or to contain debris or prevent messes during painting

how to glue pvc tarpaulin?

1. Preparation

Leave 2 inches of space on all sides to cut the patch.

Round the corners for best results.

Use thinner to clean the surface.

2. Application

Sand any smooth surface for extra hold.

Apply adhesive on both sides.

Wait 2-5 minutes until the glue is tacky.

3. Attach

Press the patch firmly onto the tarp.

Use a roller to keep the pressure even.

Let dry for 1 hour. The effect is strongest after 1 day.

What are the reasons for PVC tarpaulin fading?

Fading mainly refers to the color change of plastic PVC coated tarpaulin material fabric due to the influence of external factors. Of course, from the perspective of the PVC coated fabric canvas tarpaulin factory, the fading of PVC coated tarpaulin is related to the light resistance, oxygen resistance, heat resistance, acid and alkali resistance of the color powder and the characteristics of the resin used. If inferior raw materials and additives are used, this will cause the durable coated PVC tarpaulin material to fade or fade easily under normal use.

When using PVC tarps, it’s also worth taking a closer look at each factor:

Exposure to UV radiation

PVC vinyl coated polyester is susceptible to UV degradation due to its chemical composition. PVC contains molecules called polymers that break down when exposed to ultraviolet (UV) radiation from sunlight. Over time, this causes the material to become weak, brittle, and lose color. We often add UV stabilizers to our PVC formulas to mitigate this effect, but prolonged exposure to sunlight can still cause discoloration. Our Chinese heavy duty PVC tarp material can withstand 15-20 years of sunlight exposure outdoors.

Chemical exposure

PVC tarps can come into contact with a variety of chemicals during use, storage, or cleaning. Certain chemicals can react with PVC molecules, changing their structure and causing discoloration. For example, strong acids or bases, such as bleach or ammonia-based cleaners, can cause a chemical reaction in PVC tarps, causing the fabric material to discolor or fade. It’s important to avoid using harsh chemicals on PVC vinyl tarps and follow the manufacturer’s cleaning and maintenance recommendations.

Heat

High temperatures can accelerate the degradation of PVC tarp materials, causing them to discolor. When exposed to heat, PVC molecules can undergo chemical reactions that change their color or cause them to break down. This effect is particularly noticeable in areas with hot climates or during the summer months, when tarps are exposed to intense sunlight and heat for extended periods of time. Storing PVC tarps in a cool, dark area when not in use can help mitigate heat-related discoloration.

Poor-quality pigments/additives

The quality of pigments and additives used in PVC formulations can significantly affect the material's resistance to rust. High-quality pigments and UV stabilizers are essential to maintaining the color and integrity of high-breaking-strength PVC tarps over the long term. Poor-quality or insufficient additives may not provide adequate protection from UV rays or chemicals, making plastic PVC-coated tarps more susceptible to discoloration and degradation.

How to maintain PVC Tarpaulin?

Here are some tips for maintaining a PVC tarpaulin:

Cleaning

Remove loose debris with a brush, broom, or cloth, then wash with a mild soap or detergent solution and water. You can use a soft brush, sponge, or cloth to scrub the tarp, and rinse thoroughly with clean water.

Storage

Store the tarpaulin in a cool, dry place out of direct sunlight, such as a shed, cellar, attic, or utility room. Keep it off the floor and away from walls, and avoid folding it when it's damp, as this can lead to mold or mildew.

Inspection

Regularly check the tarpaulin for signs of wear and tear, like holes or frayed edges, and repair any damage promptly.

Protection

Sunlight can weaken the tarpaulin's material and fade its colors, so you can also apply a UV protectant spray. When folding or wrapping the tarpaulin, try to do so neatly to prevent wrinkles and creases.

PVC Tarpaulin is a kind of waterproof material, which including the knife coated / Coated /Laminated tarpaulin and with the big range of application like truck cover, side curtain, awning, tent, printing material, swimming pool liner, water tank, and fish tank as well as the membrane. The warranty time is from 3 months to 20 years depend on the different chemcial recipe.

REEVOO is one of the leading China pvc tarpaulin manufacturers and suppliers, and we are also a professional company and factory, welcome to wholesale pvc tarpaulin products from us.